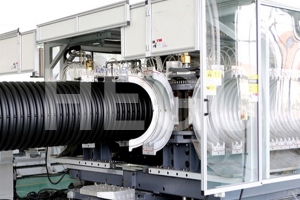

Double Wall corrugated drain pipe machine also named Culvert Pipe Making Machine , it adopts extruding and forming process, it has the features of reliable quality and high efficiency. Compared with other plastic pipe wall structure, double wall corrugated pipe has excellent wall structure design,its low weight reach the lower production cost and improve the market competitiveness. It is widely used in various field instead of concrete pipe and iron pipes, because it has excellent features such as: easy connected and accessories installed, and quality reliable.

110 mm - 250 mm PE PVC PP EVA PA Plastic double-wall Corrugated Pipe Machine

Technical parameter of Culvert Pipe Machine/Corrugated Drain Pipe Machine

| Model | SBG110 | SBG250 | SBG300 (high speed machine) |

| Pipe diameter (mm) | 50-110MM | DN/ID 50-250 | ID100-ID300mm |

| Extruder model | SJ65/33SJ-65/30 | SJ-90/30 SJ-75/30 |

SJ-90/33SJ-75/33 |

| Die head,mould | 50-110MM | 50-250mm | 100-300mm |

| Forming machine model | SBGC-110 | SBGC-250 | SBGC-300 |

| Spray cooling tank | SGL-110 | SGL-250 | SGL-300 |

| Non-dust cutting machine | SGQ110 | SGQ-250 | SGQ-300 |

| Stacker | SGD-110 | SGD-250 | SGD-300 |

| Dimension (m) | 20x4.5x3.5 | 28×4.5×3.8 | 35m×6.8m×4m |

Details of 110 mm - 250 mm double wall corrugated pipe extrusion machine

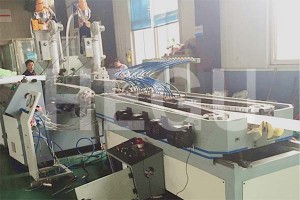

Curlver Pipe Machine/Double Wall corrugated pipe machine consists of

1.Extruder

| material | extruder type |

| PVC | conical double screw extruder |

| PE,PP | high-effective single screw extruder |

2.Die head

Materail: high quality alloy steel, nitrogen treatment

Equipped with stainless steel heater

The die head structure designed reasonably, running channel distribute uniformly, it could ensure extrusion steadily.

3.Mould

Quantity: 48 pairs for 110-250 mm

Material: Adopt good mechanical properties cast aluminum and process high fatigue strength,and good abrasion resistance.

4.Forming machine

Material : High quality alloy steel

Slide rail: Equipped with silde rail processed under special way, and process high strength and good abrasion resistance.

5.Cooling systerm:

High efficency cooling systerm could be gurantee the quality of forming.

Lubrication systerm: Equipped with centralized lubrication device, automatic quantitative lubrication.

Manual adjustment system : Used for accurately adjusting the relative position between forming and mould mouth.

6. non-dust cutting machine

7. Stacker for 110-250 mm double wall corrugated pipe

Pneumatic control, fixed-length automatic overturn

The cutting machine is equipped with dust collection device and pipe length meter.

1, WARRANTY TERMS:

1.1 WARRANTY PERIOD: 12 MONTHS, STARTING FROM THE FIRST DAY OF RUNNING MACHINES IN CUSTOMER’S WAREHOUSE

1.2 SELLER SHALL GRANT: SERVICES AND SPARE PARTS, FREE-OF-CHARGE SERVICE THROUGHOUT THE ENTIRE EQUIPMENT WARRANTY PERIOD.

1.3 LIFELONG SERVICE: THE SELLER SHOULD PROVIDE LIFELONG SERVICE FOR THE SOLD GOODS, THE BUYER PAY FOR NEEDED SPARE PARTS AFTER THE 12MONTHS WARRANTY TERMS.

2, DELIVERY CONDITIONS:

2.1 DELIVERY CONDITION: FOB QINGDAO PORT.

2.2 DELIVERY TERM: WITHIN 60 WORKING DAYS AFTER RECEIPT OF ADVANCED PAYMENT, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION. THE SELLER SHOULD FINISH PACKING OF GOODS AND READY FOR SHIPMENT WITHIN 15 WORKING DAYS AFTER THE SELLER RECEIPT THE FULL PAYMENT.

2.3 SUPERVISION OF LOADING:THE SELLER SHOULD INFORM THE BUYER EXACTLING LOADING TIME, THE BUYER CAN ARRANGE FOR SUPERVISION OF LOADING.

3, INSPECTION:

WHEN THE MACHINE FINISHED, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION BEFORE SHIPMENT, THE SELLER GUARANTY GOOD PERFORMANCE OF ALL THE SOLD GOODS.THE SELLER UNDERTAKE THE MATERIAL COST FOR THE MACHINE INSPECTION IN SELLER’S FACTORY. THE BUYER SHOULD COME TO SELLER’S FACTORY TO DO THE INSPECTION WORK, OR THE BUYER COULD ENTRUST ANY THIRD PARTT TO COME TO SELLER’S FACTORY TO DO THE INSPECTION WORK.

4, INSTALLATION AND EQUIPMENT COMMISSIONING:

IF THE BUYER REQUIRES, THE SELLER SHOULD SEND TECHNICIAN TEAM TO BUYER’S FACTORY FOR INSTALLATION AND TESTING THE WHOLE LINE.

If any interest to our machines, please kindly feel free to contact us:

Email: info@tongsanextruder.com info@wpcmachinery.com

Phone: 0086-13953226564

TEL:0086-532-82215318

Address: The West End And South Side Of Yangzhou Road,Jiaozhou City,Qingdao,China