It adheres on the tenet "Honest, industrious, enterprising, innovative" to develop new items frequently. It regards buyers, success as its very own success. Let us produce prosperous future hand in hand for 2019 Latest Design China Dhr3000 Automatic Plastic Sheet Welding/ Rolling Machine/HDPE/PP/PE Welding Equipment/Pph PVC Plastic Board Machine, Our skilled complex workforce is going to be wholeheartedly at your assistance. We sincerely welcome you to definitely pay a visit to our site and firm and deliver us your inquiry.

It adheres on the tenet "Honest, industrious, enterprising, innovative" to develop new items frequently. It regards buyers, success as its very own success. Let us produce prosperous future hand in hand for China Plastic Sheet Bending, Sheet Plastic Bending Process, We hope we can establish long-term cooperation with all of the customers. And hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need!

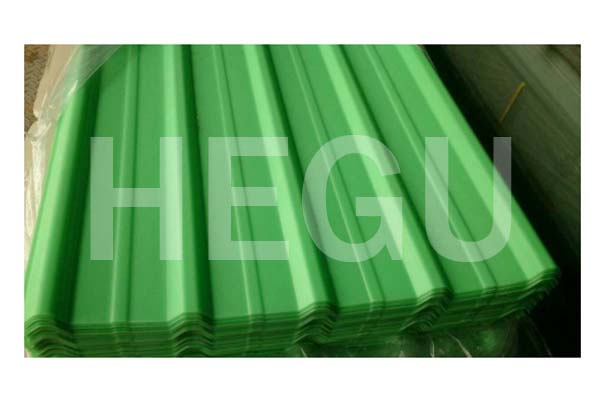

PVC corrugated roof tile extrusion machine

| Features | This production line adopts conical double-screw extruder, and it is capable of producing wavy products with PVC powder material. PVC wavy plate holds advantages of strong intensity, compact resistance, long life span, easy to execute and well decoration effect, which is widely used in fields of construction, decoration, and so on, and it is an ideal institute for asbestos shingle and glass steel tile. |

| Extruder | Specially designed screw ensures the good plasticization, stable extruding and high output. Super noiseless air cooling system and compulsive closed loop cover of the barrel guarantee favorable heat conduction and discharge. |

| Reduction gearbox | Reduction gearbox adopts sound insulating design. All gears were under high hardness treatment, and combined with compulsive lubricating system, to ensure that the reduction gearbox work steadily and quietly. |

| Extruding mould | It is of special multi-channel design, which guarantees large width and stable extruding of plastic. The gap of die lip can be adjusted freely. |

| Forming unit | The suitable design ensures quick forming and precise size. |

| Tractor | The tractor is of simple two-roller design with the distance of rollers being adjusted freely. It adopts stepless frequency control, which ensures various extrusion speeds available to lay powerful guarantee on the stable operating after forming. |

| Cutting machine | It is of reasonable cutting mode with blades of high quality alloy steel to ensure the quick, stable and flat cutting. |

| Controlling system | Various kinds of controlling system are available to satisfy customers’demands. |

| Width of products | 600mm-2000mm |

| Thickness of products | 1mm-4mm |

1, WARRANTY TERMS:

1.1 WARRANTY PERIOD: 12 MONTHS, STARTING FROM THE FIRST DAY OF RUNNING MACHINES IN CUSTOMER’S WAREHOUSE

1.2 SELLER SHALL GRANT: SERVICES AND SPARE PARTS, FREE-OF-CHARGE SERVICE THROUGHOUT THE ENTIRE EQUIPMENT WARRANTY PERIOD.

1.3 LIFELONG SERVICE: THE SELLER SHOULD PROVIDE LIFELONG SERVICE FOR THE SOLD GOODS, THE BUYER PAY FOR NEEDED SPARE PARTS AFTER THE 12MONTHS WARRANTY TERMS.

2, DELIVERY CONDITIONS:

2.1 DELIVERY CONDITION: FOB QINGDAO PORT.

2.2 DELIVERY TERM: WITHIN 60 WORKING DAYS AFTER RECEIPT OF ADVANCED PAYMENT, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION. THE SELLER SHOULD FINISH PACKING OF GOODS AND READY FOR SHIPMENT WITHIN 15 WORKING DAYS AFTER THE SELLER RECEIPT THE FULL PAYMENT.

2.3 SUPERVISION OF LOADING:THE SELLER SHOULD INFORM THE BUYER EXACTLING LOADING TIME, THE BUYER CAN ARRANGE FOR SUPERVISION OF LOADING.

3, INSPECTION:

WHEN THE MACHINE FINISHED, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION BEFORE SHIPMENT, THE SELLER GUARANTY GOOD PERFORMANCE OF ALL THE SOLD GOODS.THE SELLER UNDERTAKE THE MATERIAL COST FOR THE MACHINE INSPECTION IN SELLER’S FACTORY. THE BUYER SHOULD COME TO SELLER’S FACTORY TO DO THE INSPECTION WORK, OR THE BUYER COULD ENTRUST ANY THIRD PARTT TO COME TO SELLER’S FACTORY TO DO THE INSPECTION WORK.

4, INSTALLATION AND EQUIPMENT COMMISSIONING:

IF THE BUYER REQUIRES, THE SELLER SHOULD SEND TECHNICIAN TEAM TO BUYER’S FACTORY FOR INSTALLATION AND TESTING THE WHOLE LINE.

If any interest to our machines, please kindly feel free to contact us:

Email: info@tongsanextruder.com info@wpcmachinery.com

Phone: 0086-13953226564

TEL:0086-532-82215318

Address: The West End And South Side Of Yangzhou Road,Jiaozhou City,Qingdao,China

-

Wholesale OEM/ODM Plastic Shredder Grinder Crus...

-

100% Original China Sj Series PE Single Wall Co...

-

2019 New Style Pvc Wpc Foam Board Making Machin...

-

Good Quality Twin Screw extrusion large diamete...

-

Supply OEM automatic metal roofing sheet corrug...

-

OEM China China Plastic PVC PP PE Single Wall C...