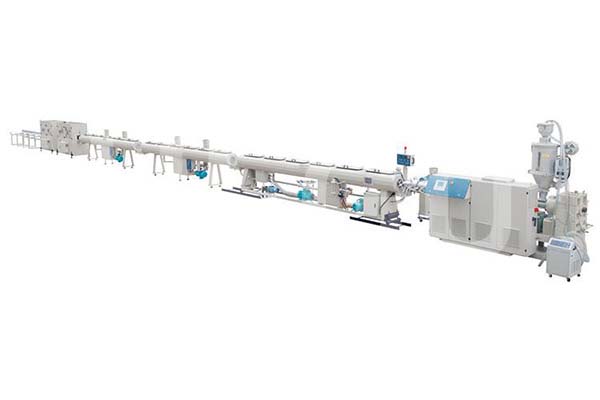

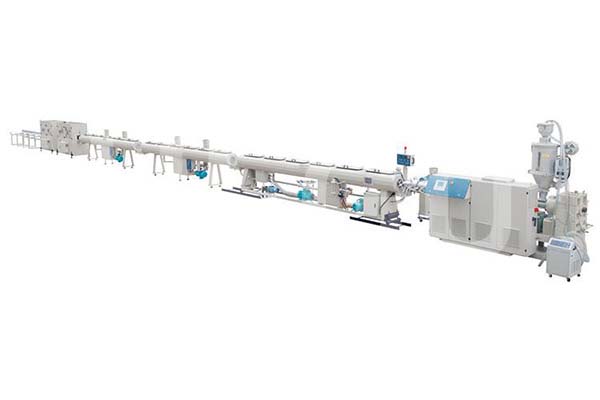

Factory Outlets Double Screw Sheet Production Line - Plastic profile machine PVC ceiling machine – WOOD-PLASTIC Detail:

Total line:

| 1, Used condition :380—420V/3phase /50HZ |

| 2, Suitable material:PVC powder and the accessory material (we will supply the formula to you ) |

| 3, Applicant:PVC window and door profiles |

SJSZ-65/132 conical double screw extruder

Mould and sizing sleeve :

| We will supply the mould and sizing sleeve according to the samples . | |

| As the samples photos you attached | For the acoustic lining : one mould, cause the final product is big |

| For the smaller pieces such as pinch plate , double mould | |

| Can produce the pinch plate two pieces together | |

vacuum sizing device:

| The total length of vacuum sizing device : 6000mm |

| Material of water container : stainless steel |

| The joint of cooling water pipes : quantity : 20 piecesThe joint of vacuum pipes : quantity : 20 pieces |

| Landscape orientation adjustment space :80mm Central height adjustment space :80mmPortrait adjustment space :600mm |

| Go forward and recede equipped with auto pushing pole , power : 1.1kw |

Hauling off device:

| The maximum clamping width : 300mm The maximum clamping height : 120mm |

| Maximum traction : 30000N |

| Hauling off speed : 0-5m/min, can be adjusted must be match with extruder |

| Motor power :3KW |

| With pneumatic fasten adjustment function |

Cutting device:

| The diameter of saw blade : 400mm |

| Maximum cutting profile : 250mm |

| Cutting speed : 5m/s |

| Motor power :2.2KW |

storage device

Control system of total line :

| Schneider low-voltage electric applicant , OMRON intelligent temperature controller , Siemens speed frequency regulator |

Auxiliary machinery:

SHRL—200/500 material mixing device

| Function : To make the PVC powder together with accessory materials |

| Total volume : for hot mixing device 200L ; for cold mixing device :500LValid volume : for hot mixing device 150L ; for cold mixing device :320L |

| Stirring blade :2 pieces for hot mixing device , 1 piece for cold mixing device |

| Material input at one time : 65KG |

| Rotary speed of hot mixing stirring blade :475/950 r.p.m Rotary speed of cold mixing stirring blade : 90 r.p.m |

| Material mixing time : 6-10 minutesMaterial cooling time :8-12 minutes |

| Heating mode : auto friction or electric heatingCooling mode : water circulate |

| Motor power : 30/42KW ; capacity : about 350kg/h |

SWP360 crusher:

| Moving blade : quantity : 3 piecesFixed blade : quantity :2 pieces |

| Diameter of crushing chamber : 360mm Diameter of crushing sieve :10mmDiameter of crushed scrape : 3-5mm capacity : 300-400kg/h |

| Motor power : 11kw |

Product detail pictures:

Related Product Guide:

PVC Pipes – Types of PVC Pipes and Their Usage

The Insider Scoop on a Vacuum Formable Plastic Sheet

Persisting in "High top quality, Prompt Delivery, Aggressive Price", now we have established long-term cooperation with customers from the two overseas and domestically and get new and aged clients' large comments for Factory Outlets Double Screw Sheet Production Line - Plastic profile machine PVC ceiling machine – WOOD-PLASTIC, The product will supply to all over the world, such as: Puerto Rico, Croatia, India, Our company has built stable business relationships with many well-known domestic companies as well as oversea customers. With the goal of providing high quality products to customers at low cots, we are committed to improving its capacities in research, development, manufacturing and management. We have honored to receive recognition from our customers. Till now we have passed ISO9001 in 2005 and ISO/TS16949 in 2008. Enterprises of "quality of survival, the credibility of development" for the purpose, sincerely welcome domestic and foreign businessmen to visit to discuss cooperation.

1, WARRANTY TERMS:

1.1 WARRANTY PERIOD: 12 MONTHS, STARTING FROM THE FIRST DAY OF RUNNING MACHINES IN CUSTOMER’S WAREHOUSE

1.2 SELLER SHALL GRANT: SERVICES AND SPARE PARTS, FREE-OF-CHARGE SERVICE THROUGHOUT THE ENTIRE EQUIPMENT WARRANTY PERIOD.

1.3 LIFELONG SERVICE: THE SELLER SHOULD PROVIDE LIFELONG SERVICE FOR THE SOLD GOODS, THE BUYER PAY FOR NEEDED SPARE PARTS AFTER THE 12MONTHS WARRANTY TERMS.

2, DELIVERY CONDITIONS:

2.1 DELIVERY CONDITION: FOB QINGDAO PORT.

2.2 DELIVERY TERM: WITHIN 60 WORKING DAYS AFTER RECEIPT OF ADVANCED PAYMENT, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION. THE SELLER SHOULD FINISH PACKING OF GOODS AND READY FOR SHIPMENT WITHIN 15 WORKING DAYS AFTER THE SELLER RECEIPT THE FULL PAYMENT.

2.3 SUPERVISION OF LOADING:THE SELLER SHOULD INFORM THE BUYER EXACTLING LOADING TIME, THE BUYER CAN ARRANGE FOR SUPERVISION OF LOADING.

3, INSPECTION:

WHEN THE MACHINE FINISHED, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION BEFORE SHIPMENT, THE SELLER GUARANTY GOOD PERFORMANCE OF ALL THE SOLD GOODS.THE SELLER UNDERTAKE THE MATERIAL COST FOR THE MACHINE INSPECTION IN SELLER’S FACTORY. THE BUYER SHOULD COME TO SELLER’S FACTORY TO DO THE INSPECTION WORK, OR THE BUYER COULD ENTRUST ANY THIRD PARTT TO COME TO SELLER’S FACTORY TO DO THE INSPECTION WORK.

4, INSTALLATION AND EQUIPMENT COMMISSIONING:

IF THE BUYER REQUIRES, THE SELLER SHOULD SEND TECHNICIAN TEAM TO BUYER’S FACTORY FOR INSTALLATION AND TESTING THE WHOLE LINE.

If any interest to our machines, please kindly feel free to contact us:

Email: info@tongsanextruder.com info@wpcmachinery.com

Phone: 0086-13953226564

TEL:0086-532-82215318

Address: The West End And South Side Of Yangzhou Road,Jiaozhou City,Qingdao,China

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!

-

OEM China Floor Tile Making Machine Price - PV...

-

18 Years Factory Small Extruder Machine - PVC ...

-

China Gold Supplier for Transparent Pvc Sheet M...

-

Competitive Price for Conical Twin Screw Extrud...

-

Renewable Design for Pe/pvc Single Wall Corruga...

-

Factory wholesale Pvc Pipe Machine Cost - Plas...