With our leading technology also as our spirit of innovation,mutual cooperation, benefits and development, we are going to build a prosperous future jointly with your esteemed company for ODM Manufacturer Dwc Plastic Pe Hdpe Pvc Single Double Wall Corrugated Pipe Making Extrusion Production Line, We welcome you to definitely pay a visit to our manufacturing unit and anticipate creating welcoming organization relationships with consumers at your house and overseas inside the in close proximity to foreseeable future.

With our leading technology also as our spirit of innovation,mutual cooperation, benefits and development, we are going to build a prosperous future jointly with your esteemed company for , We aim to build a famous brand which can influence a certain group of people and light up the whole world. We want our staff to realize self-reliance, then achieve financial freedom, lastly obtain time and spiritual freedom. We do not focus on how much fortune we can make, instead we aim to obtain high reputation and be recognized for our products and solutions. As a result, our happiness comes from our clients satisfaction rather than how much money we earn. Ours team will do best in your case always.

Specifications

1.get CE

2.high speed and high quality

3.longlife and service

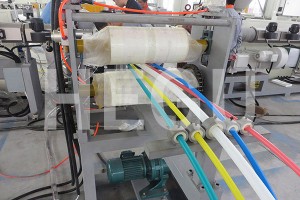

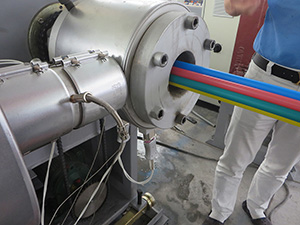

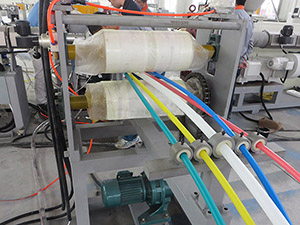

PE Carbon Spiral Pipe Making Machine

This production line is mainly used to produce PE spiral pipes which are largely used as protecting sleeves of optic or electric cable, and they are increasingly used in fields of electricity, telecom, post activities, constructions of express way, port, etc. These pipes are characterized by high intensity and tenancy, erosion resistance, constant shape and easy transportation and execution, etc. They can be processed and bent into long pipes with various radians. Owing to these advantages, they are very popular with clients engaged in many fields.

Features of production line:

1. Dedicated single-screw extruder is especially used for producing polyolefin products, and the specialized separating type mix-melting screw possesses features of high-speed extrusion and plasticization, etc.

2. The pipe die head is designed in standard, and the reasonable flowing path ensures smoothness of the inside and outside walls of the pipe. The way of assembling the die head is designed according to the client’s requirement, which saves much room.

3. Both scientifically designed copper spiral sizing sheath and the powerful inhaling vacuum device contribute to high extrusion of the pipes.

4. The tank is made of stainless steel, and automatic controller is used to control the liquid level. The peculiar spraying nozzle brings about effective cooling and the motor ensures longitudinal movement and three-dimensional adjustment in terms of the directions of upward, downward, left and right.

5. The special sizing and cooling mode enable the production line to produce pipes whose diameter range is from 25mm to 200mm, at a speed of 0.8to 1.5 meters per minute.

The main technique parameter

|

ParameterModel |

SJ-65B |

SJ-90B |

| Length dia. ratio | 30:1 | 30:1 |

| Produced pipe range | 25-100 | 75-200 |

| Production power(kg/h) | 20-60 | 50-100 |

| Production speed (m/min) | 0.8-1.5 | 0.8-1.5 |

| Gross power (kw) | 32.7 | 50.2 |

1, WARRANTY TERMS:

1.1 WARRANTY PERIOD: 12 MONTHS, STARTING FROM THE FIRST DAY OF RUNNING MACHINES IN CUSTOMER’S WAREHOUSE

1.2 SELLER SHALL GRANT: SERVICES AND SPARE PARTS, FREE-OF-CHARGE SERVICE THROUGHOUT THE ENTIRE EQUIPMENT WARRANTY PERIOD.

1.3 LIFELONG SERVICE: THE SELLER SHOULD PROVIDE LIFELONG SERVICE FOR THE SOLD GOODS, THE BUYER PAY FOR NEEDED SPARE PARTS AFTER THE 12MONTHS WARRANTY TERMS.

2, DELIVERY CONDITIONS:

2.1 DELIVERY CONDITION: FOB QINGDAO PORT.

2.2 DELIVERY TERM: WITHIN 60 WORKING DAYS AFTER RECEIPT OF ADVANCED PAYMENT, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION. THE SELLER SHOULD FINISH PACKING OF GOODS AND READY FOR SHIPMENT WITHIN 15 WORKING DAYS AFTER THE SELLER RECEIPT THE FULL PAYMENT.

2.3 SUPERVISION OF LOADING:THE SELLER SHOULD INFORM THE BUYER EXACTLING LOADING TIME, THE BUYER CAN ARRANGE FOR SUPERVISION OF LOADING.

3, INSPECTION:

WHEN THE MACHINE FINISHED, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION BEFORE SHIPMENT, THE SELLER GUARANTY GOOD PERFORMANCE OF ALL THE SOLD GOODS.THE SELLER UNDERTAKE THE MATERIAL COST FOR THE MACHINE INSPECTION IN SELLER’S FACTORY. THE BUYER SHOULD COME TO SELLER’S FACTORY TO DO THE INSPECTION WORK, OR THE BUYER COULD ENTRUST ANY THIRD PARTT TO COME TO SELLER’S FACTORY TO DO THE INSPECTION WORK.

4, INSTALLATION AND EQUIPMENT COMMISSIONING:

IF THE BUYER REQUIRES, THE SELLER SHOULD SEND TECHNICIAN TEAM TO BUYER’S FACTORY FOR INSTALLATION AND TESTING THE WHOLE LINE.

If any interest to our machines, please kindly feel free to contact us:

Email: info@tongsanextruder.com info@wpcmachinery.com

Phone: 0086-13953226564

TEL:0086-532-82215318

Address: The West End And South Side Of Yangzhou Road,Jiaozhou City,Qingdao,China

-

China New Product China Band PVC Plastic Single...

-

China Cheap price China PVC Plastic Conduit Pip...

-

Reasonable price Flexible Corrugated Pipe Machi...

-

China New Product China PP-R Pipe Extrusion Mak...

-

Manufacturer for Indoor Click Locking Spc/ Rvp/...

-

Factory directly China PUR Profile Wrapping Mac...