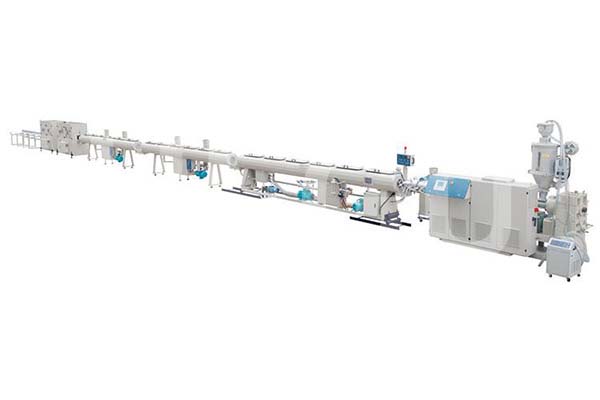

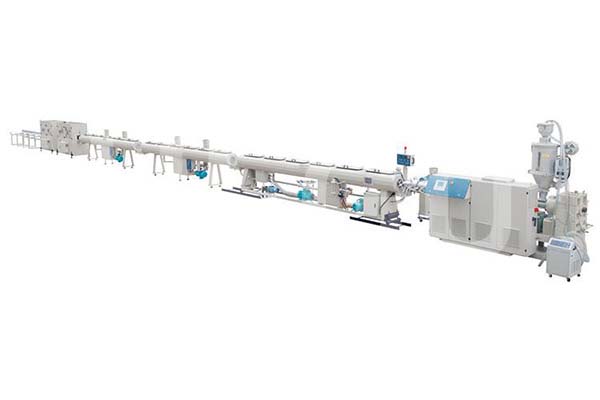

One of Hottest for Portable Edge Banding Machine - Plastic recycling machine PP PE PS PC ABS cold granulating production line – WOOD-PLASTIC Detail:

Plastic cold cut granulating production line

Brief Introduction

This machine line is mainly used for plastic with high melt index and high viscosity such as PP,PE,PS,HIPS,ABS,PC etc.It adopts parallel double screw extruder and single screw extruder,the specially designed screw is applicable to the granulating ,dyeing.reproduction for various materials.Hob cutting type granule cutter is characterized by stable rotation,

even cutting ,energy and electricity saving and safely operating etc.

We can make different types extruder according to the customized production output.

The specially design mould makes the granules more even.

The specially designed blade and hardening treatment make the lifespan of the equipment longer.

Product detail pictures:

Related Product Guide:

The Insider Scoop on a Vacuum Formable Plastic Sheet

Why Do People Prefer PVC Pipes For Various Purposes

We have probably the most state-of-the-art output equipment, experienced and qualified engineers and workers, recognized good quality manage systems plus a friendly skilled income workforce pre/after-sales support for One of Hottest for Portable Edge Banding Machine - Plastic recycling machine PP PE PS PC ABS cold granulating production line – WOOD-PLASTIC, The product will supply to all over the world, such as: Bahrain, Belgium, Ecuador, We'll initiate the second phase of our development strategy. Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. If you are interested in any of our products and solutions or would like to discuss a custom order, make sure you feel free to contact us. We've been looking forward to forming successful business relationships with new clients around the world in the near future.

1, WARRANTY TERMS:

1.1 WARRANTY PERIOD: 12 MONTHS, STARTING FROM THE FIRST DAY OF RUNNING MACHINES IN CUSTOMER’S WAREHOUSE

1.2 SELLER SHALL GRANT: SERVICES AND SPARE PARTS, FREE-OF-CHARGE SERVICE THROUGHOUT THE ENTIRE EQUIPMENT WARRANTY PERIOD.

1.3 LIFELONG SERVICE: THE SELLER SHOULD PROVIDE LIFELONG SERVICE FOR THE SOLD GOODS, THE BUYER PAY FOR NEEDED SPARE PARTS AFTER THE 12MONTHS WARRANTY TERMS.

2, DELIVERY CONDITIONS:

2.1 DELIVERY CONDITION: FOB QINGDAO PORT.

2.2 DELIVERY TERM: WITHIN 60 WORKING DAYS AFTER RECEIPT OF ADVANCED PAYMENT, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION. THE SELLER SHOULD FINISH PACKING OF GOODS AND READY FOR SHIPMENT WITHIN 15 WORKING DAYS AFTER THE SELLER RECEIPT THE FULL PAYMENT.

2.3 SUPERVISION OF LOADING:THE SELLER SHOULD INFORM THE BUYER EXACTLING LOADING TIME, THE BUYER CAN ARRANGE FOR SUPERVISION OF LOADING.

3, INSPECTION:

WHEN THE MACHINE FINISHED, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION BEFORE SHIPMENT, THE SELLER GUARANTY GOOD PERFORMANCE OF ALL THE SOLD GOODS.THE SELLER UNDERTAKE THE MATERIAL COST FOR THE MACHINE INSPECTION IN SELLER’S FACTORY. THE BUYER SHOULD COME TO SELLER’S FACTORY TO DO THE INSPECTION WORK, OR THE BUYER COULD ENTRUST ANY THIRD PARTT TO COME TO SELLER’S FACTORY TO DO THE INSPECTION WORK.

4, INSTALLATION AND EQUIPMENT COMMISSIONING:

IF THE BUYER REQUIRES, THE SELLER SHOULD SEND TECHNICIAN TEAM TO BUYER’S FACTORY FOR INSTALLATION AND TESTING THE WHOLE LINE.

If any interest to our machines, please kindly feel free to contact us:

Email: info@tongsanextruder.com info@wpcmachinery.com

Phone: 0086-13953226564

TEL:0086-532-82215318

Address: The West End And South Side Of Yangzhou Road,Jiaozhou City,Qingdao,China

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.

-

Factory supplied Granulation Machine - Corruga...

-

Free sample for Pvc Pipe Extrusion Machine - P...

-

OEM China Pvc Tape Extrusion Line - Plastic re...

-

PriceList for High Density Foam Block - PVC pi...

-

2017 China New Design Manual Mechanics Screen C...

-

One of Hottest for Pvc Artificial Marble Board ...