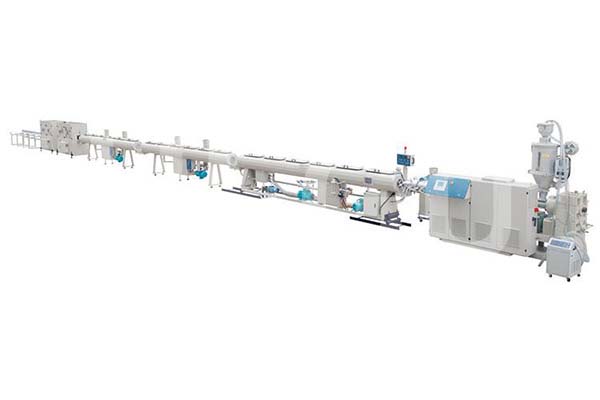

Top Suppliers China Pipe Making Machine - Plastic recycling machine Co-paraller twin screw granulating machine – WOOD-PLASTIC Detail:

This machinery is composed of parallel twin-screw extruder, granulate die head, granule cutting machine, three-grade air supplying system. The parallel twin-screw adopts modular construction, with advantages of all gear-closing and strong self-cleaning. The barrel has a good exhaust effect. The bi-metal alloy bushing is of wear-resistance and corrosion-resistance. The machines can be combined freely according to the material characteristics and production process, so it is of widely use. Die head is made from high-quality mould steel, under hard chrome plating treatment. The reasonable-distributed material running channel can ensure the uniform extrusion of the granules without mutual influence. The unique three-dimensional cooling structure and the new-type multi powerful blower cooling mode make the cooling effect better. Besides, the precise cutter ensures the even and smooth surface of the products. The speed frequency regulation meets different granulating requirements. This production line has features of high production efficiency, low energy-consumption, etc, especially applicable to the WPC granulation process.

Main Technical parameter:

|

Model |

Screw |

Screw |

L/D |

Main |

Rotating |

Capacity |

|

SJMS-60 |

60 |

2 |

28-48 |

45-55 |

0-400/600 |

90-200 |

|

SJMS-65 |

65 |

2 |

28-48 |

55-75 |

0-400/600 |

150-280 |

|

SJMS-72 |

72 |

2 |

28-48 |

90-132 |

0-400/600 |

150-400 |

|

SJMS-75 |

75 |

2 |

28-48 |

90-132 |

0-400/600 |

180-450 |

|

SJMS-95 |

95 |

2 |

28-48 |

220-280 |

0-300/400 |

450-900 |

Product detail pictures:

Related Product Guide:

PVC Pipes – Types of PVC Pipes and Their Usage

PVC Pipes Measurements

Our company has been concentrating on brand strategy. Customers' pleasure is our greatest advertising. We also source OEM service for Top Suppliers China Pipe Making Machine - Plastic recycling machine Co-paraller twin screw granulating machine – WOOD-PLASTIC, The product will supply to all over the world, such as: Saudi Arabia, Madrid, Spain, With good quality, reasonable price and sincere service, we enjoy a good reputation. Products are exported to South America, Australia, Southeast Asia and so on. Warmly welcome customers at home and abroad to cooperate with us for the brilliant future.

1, WARRANTY TERMS:

1.1 WARRANTY PERIOD: 12 MONTHS, STARTING FROM THE FIRST DAY OF RUNNING MACHINES IN CUSTOMER’S WAREHOUSE

1.2 SELLER SHALL GRANT: SERVICES AND SPARE PARTS, FREE-OF-CHARGE SERVICE THROUGHOUT THE ENTIRE EQUIPMENT WARRANTY PERIOD.

1.3 LIFELONG SERVICE: THE SELLER SHOULD PROVIDE LIFELONG SERVICE FOR THE SOLD GOODS, THE BUYER PAY FOR NEEDED SPARE PARTS AFTER THE 12MONTHS WARRANTY TERMS.

2, DELIVERY CONDITIONS:

2.1 DELIVERY CONDITION: FOB QINGDAO PORT.

2.2 DELIVERY TERM: WITHIN 60 WORKING DAYS AFTER RECEIPT OF ADVANCED PAYMENT, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION. THE SELLER SHOULD FINISH PACKING OF GOODS AND READY FOR SHIPMENT WITHIN 15 WORKING DAYS AFTER THE SELLER RECEIPT THE FULL PAYMENT.

2.3 SUPERVISION OF LOADING:THE SELLER SHOULD INFORM THE BUYER EXACTLING LOADING TIME, THE BUYER CAN ARRANGE FOR SUPERVISION OF LOADING.

3, INSPECTION:

WHEN THE MACHINE FINISHED, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION BEFORE SHIPMENT, THE SELLER GUARANTY GOOD PERFORMANCE OF ALL THE SOLD GOODS.THE SELLER UNDERTAKE THE MATERIAL COST FOR THE MACHINE INSPECTION IN SELLER’S FACTORY. THE BUYER SHOULD COME TO SELLER’S FACTORY TO DO THE INSPECTION WORK, OR THE BUYER COULD ENTRUST ANY THIRD PARTT TO COME TO SELLER’S FACTORY TO DO THE INSPECTION WORK.

4, INSTALLATION AND EQUIPMENT COMMISSIONING:

IF THE BUYER REQUIRES, THE SELLER SHOULD SEND TECHNICIAN TEAM TO BUYER’S FACTORY FOR INSTALLATION AND TESTING THE WHOLE LINE.

If any interest to our machines, please kindly feel free to contact us:

Email: info@tongsanextruder.com info@wpcmachinery.com

Phone: 0086-13953226564

TEL:0086-532-82215318

Address: The West End And South Side Of Yangzhou Road,Jiaozhou City,Qingdao,China

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!

-

Fast delivery Water Drinking Cups Sheet Extrusi...

-

Rapid Delivery for Pvc Laminating Press Machine...

-

Massive Selection for Flexible Hose Machine - ...

-

Best Price for Production Line Counting Machine...

-

Professional Design Pvc Sheet Machine Price - ...

-

Best quality Recycled Plastic Sheet Machine - ...